Axle Spindle

HIGH QUALITY PRECISE MANUFACTURER &SUPPLIER CONTACT US

Leading the Way in Axle Spindle Innovation: Commitment to Excellence and Customer Satisfaction

Our axle spindles are renowned for their robust construction, high durability, and exceptional performance under extreme conditions. Designed to meet the rigorous demands of both commercial and industrial applications, our products offer enhanced load-bearing capacities and reduced maintenance costs, making them the preferred choice in automotive, agricultural machinery, and heavy equipment sectors. Each spindle is crafted using precision engineering techniques, ensuring maximum reliability and longevity.

We pride ourselves on our expertise and authority in the axle spindle market, which is bolstered by our commitment to research and development. This focus has not only kept us at the forefront of technological advancements but also ensures that we remain responsive to the evolving needs of our clients.

Our customer service philosophy centers on providing comprehensive support and swift resolution of any issues, backed by an efficient after-sales service team. We are dedicated to ongoing improvement and innovation, constantly refining our products and processes to exceed industry standards and customer expectations. This relentless pursuit of excellence defines our market presence and underscores our commitment to not just meeting but surpassing the needs of our valued clients.

The advantages of an Axle Spindle compared to a Torsion Axle

| Feature | Axle Spindle | Torsion Axle |

|---|---|---|

| Load Handling | Typically supports higher load capacities. | Generally offers moderate load capacities. |

| Maintenance | Easier to repair and replace individual components like bearings. | Lower maintenance due to fewer moving parts, but more complex repairs if issues arise. |

| Cost | Often less expensive in initial setup for heavy-duty applications. | Can be more costly due to integrated design and specialized components. |

| Ride Quality | Dependent on the overall suspension system; potentially less smooth. | Provides a smoother ride due to independent wheel suspension. |

| Customization | High customization in terms of size, shape, and material. | Less flexible in customization due to the integrated design. |

| Durability | Very durable, especially with proper maintenance. | Durability depends on internal rubber components, which can degrade. |

| Suitability for Terrain | Suitable for rough and uneven terrain when combined with appropriate suspension. | Better suited for smooth terrains; performance may vary on rough terrains. |

Axle Spindle for sale

-

1750lbs&3500lbs Capacity Trailer Drop Spindles for Trailer Axle Parts

-

China Engineering and Construction Machinery Axle Spindle with Forged Technics

-

China Hot Forged Axle Spindle for Heavy Duty Trucks and Construction Machinery

-

Factory Price Heavy Duty Forging Axle Trailer Spindle

-

Light Trailer Axle Spindle with Ts16949 Standard

-

OEM Trailer Parts Drop Axle Forging Spindle

What is the Axle Spindle?

An axle spindle is a crucial component in the wheel assembly of vehicles, primarily serving as the part on which the wheel and its associated components rotate. Positioned at the end of the axle, the spindle provides a mounting surface for the wheel bearings, which allow the wheel to spin freely while maintaining alignment and handling the weight of the vehicle.

Axle spindles are used in a variety of vehicles, including cars, trucks, trailers, and agricultural equipment. They are designed to withstand heavy loads and stress, ensuring durability and safety under various operating conditions. The specific design and size of an axle spindle can vary widely depending on its intended application, ranging from light-duty vehicles to heavy industrial machinery.

Features of Axle Spindle

Material Strength

Typically made from high-strength steel or alloys, axle spindles are designed to withstand heavy loads and resist wear and tear. This makes them suitable for use in harsh environments and under extreme stress conditions.

Precision Engineering

Axle spindles are manufactured with high precision to ensure they fit perfectly with other components like wheel bearings and hubs. This precision helps maintain the alignment of the wheel assembly, which is crucial for vehicle stability and handling.

Corrosion Resistance

Many axle spindles are coated to protect against rust and corrosion. This is especially important for vehicles that operate in moist or salty environments, such as those used in coastal areas or in winter conditions where roads are salted.

How the Axle Spindle Works

The axle spindle is a critical component that plays a crucial role in the operation of various mechanical systems and equipment. At the heart of the axle spindle is its primary function – to support and rotate the axle or shaft, allowing for the smooth and efficient transfer of power and motion.

The axle spindle is typically composed of a cylindrical shaft or journal that is supported by one or more bearings, usually either rolling element bearings (such as ball or roller bearings) or plain bearings. These bearings are responsible for facilitating the smooth rotation of the axle spindle, while also supporting the radial and axial loads imposed on the system.

As the axle or shaft rotates, the axle spindle transmits the torque and rotational force to the connected components, enabling the overall mechanism to function as intended. This could involve powering the wheels of a vehicle, driving a conveyor belt, or transmitting motion in a wide range of industrial machinery.

Axle Spindle Application Industry

Automotive Industry

Axle spindles are used in cars, motorcycles, and trucks, where they play a crucial role in the wheel assembly, supporting the vehicle’s weight and ensuring smooth rotation of the wheels.

Construction and Mining

Heavy-duty axle spindles are found in construction and mining equipment like loaders, dump trucks, and excavators. Their durability and strength are vital for operations in these demanding environments.

Rail Industry

Axle spindles are used in rail vehicles, including freight and passenger trains, where they are essential for wheel assemblies that must endure high loads and speeds.

Agriculture

In agricultural machinery, such as tractors and harvesters, axle spindles are essential for supporting heavy loads and enabling the mobility of these machines across various types of terrain.

Trailer Manufacturing

Trailers for both commercial and recreational use rely on axle spindles to handle significant weights and maintain stability during transport.

Manufacturing and Industrial Equipment

Various types of industrial machinery, including those used in manufacturing plants and warehouses (like forklifts), utilize axle spindles for mobility and load-bearing capabilities.

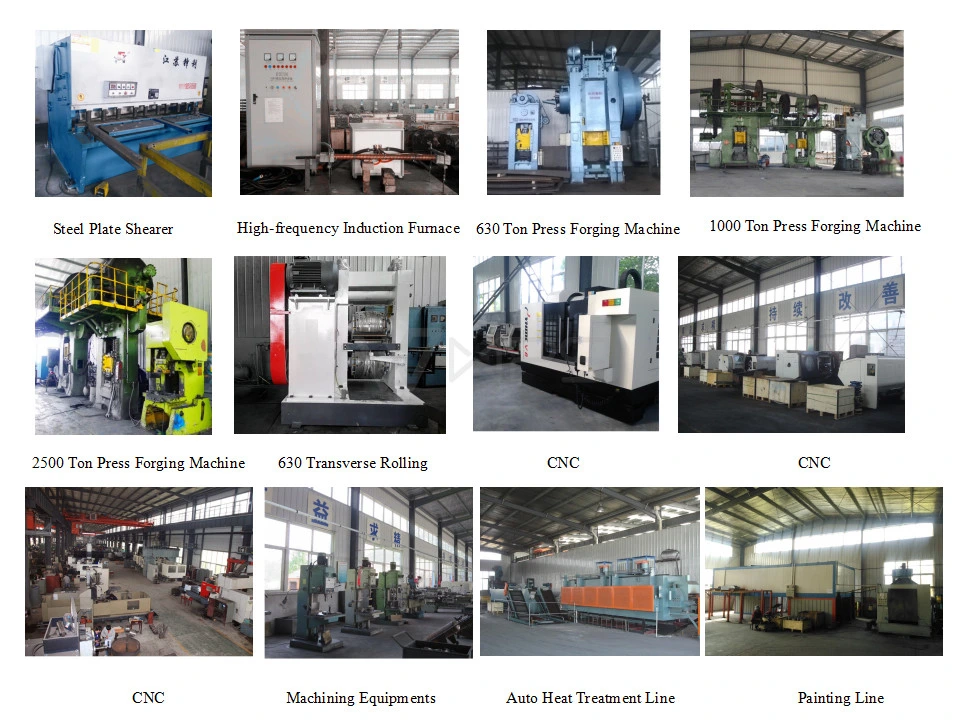

Axle Spindle’s main manufacturing process

-

Forging: The process begins with forging the metal, typically steel, to shape the rough form of the spindle. Forging involves heating the metal until it is malleable and then hammering or pressing it into the desired shape. This process enhances the metal’s grain structure, making it stronger and more resistant to fatigue.

-

Machining: After forging, the rough spindle undergoes machining to achieve precise dimensions and tolerances. Machining processes can include turning, milling, and drilling, which refine the shape and create necessary features such as grooves, threads, and bearing seats.

-

Heat Treatment: To further improve strength and durability, the axle spindle is heat-treated. Common heat treatment processes include quenching and tempering, which harden the metal and then temper it to remove brittleness while retaining its toughness.

-

Surface Treatment: Axle spindles often receive surface treatments to improve corrosion resistance and wear properties. This might include coating processes such as galvanizing, chrome plating, or applying protective paints and sealants.

-

Grinding and Polishing: After heat and surface treatments, grinding and polishing are performed to achieve a smooth finish. This step is crucial for minimizing friction and wear when the spindle operates within the wheel assembly.

-

Quality Control and Testing: Throughout the manufacturing process, rigorous quality control measures are in place. This includes dimensional checks, material composition analysis, and stress testing to ensure each spindle meets the specified standards and can withstand real-world operating conditions.

-

Assembly: Finally, additional components such as bearing units may be assembled with the spindle, depending on its design and application requirements.

Blog

Axle Spindle manufacturing materials

Carbon Steel: This is one of the most commonly used materials due to its strength and cost-effectiveness. High-carbon steel varieties are particularly favored for their ability to withstand high stress and wear.

Alloy Steel: Alloy steels are preferred for more demanding applications because they include elements like chromium, nickel, and molybdenum, which enhance their strength, toughness, and resistance to corrosion and wear. These materials are ideal for heavy-duty axle spindles that must perform under extreme conditions.

Stainless Steel: Although less common due to its cost, stainless steel is used for axle spindles in environments where corrosion resistance is paramount. It’s particularly useful in marine applications or in environments with high exposure to corrosive substances.

Forged Aluminum: For applications where weight is a critical factor, such as in certain automotive or aerospace applications, forged aluminum can be used. It provides a good strength-to-weight ratio but is generally less strong compared to steels.

Titanium Alloys: In high-end, performance-focused applications where strength, lightweight, and corrosion resistance are all critical, titanium alloys might be used. They are much more expensive than steels but offer superior properties where needed.

Installation of Axle Spindle in Mechanical Equipment

Preparation and Inspection:

Cleaning: Begin by cleaning all the components that will be involved in the assembly, including the axle spindle, hub, bearings, and any mounting hardware. This ensures that no debris or contaminants interfere with the installation.

Inspection: Carefully inspect the spindle and all related components for any signs of damage or wear. Replace any parts that appear compromised.

Installing Bearings and Seals:

Bearing Installation: Depending on the design, bearings may either be pressed onto the spindle or installed inside the hub that will be mounted on the spindle. Ensure that bearings are correctly positioned and seated.

Seal Installation: Install new seals as required to prevent lubricant from leaking and to keep contaminants out. Seals must be installed carefully to avoid damage.

Mounting the Hub:

Hub Placement: Slide the hub onto the spindle, making sure that the bearings align properly and that the assembly moves smoothly without binding or excessive play.

Securing the Hub: Secure the hub onto the spindle using a retaining nut or similar fastener. Tighten the nut to the manufacturer’s specified torque setting to ensure the hub is securely fastened yet able to rotate freely without excessive play.

Additional Components:

Install Additional Hardware: Depending on the application, you might need to attach other components at this stage, such as brake assemblies, wheels, or other hardware.

Final Assembly: Complete the assembly by installing any remaining parts such as wheel rims, tires, and caps.

Lubrication:

Greasing: Properly lubricate the spindle, bearings, and any other moving parts with suitable grease or lubricant to reduce friction and wear.

Testing:

Spin Test: Rotate the hub by hand to ensure it spins freely without noise or resistance.

Load Test: If possible, perform a load test to ensure that the assembly can handle its intended operational loads.

Final Inspection:

Check All Fasteners: Ensure all fasteners and components are securely tightened and properly seated.

Inspect for Leaks: Check for any signs of grease or lubricant leakage, which could indicate an improperly seated seal.

Why choose our company?

1. High-quality products: Our company is committed to providing the highest-quality axle spindle. Our products are precision-engineered and manufactured using advanced materials to ensure durability, reliability, and consistent performance.

2. Comprehensive Service: We pride ourselves on providing excellent customer service. Our professional team is ready to answer your questions, provide technical support, and provide solutions tailored to your needs.

3. Competitive Prices: Our company offers competitive prices without compromising quality. We believe in creating value for our customers and work hard to ensure our products fit every budget.

4. Excellent after-sales support: We know a product is only as good as the support you receive after purchasing it. Our company provides comprehensive after-sales services, including timely repair, replacement, and maintenance, ensuring that your axle spindle is in optimal condition for a more extended period.

5. Rich product range: Our company provides a variety of axle spindle shafts to meet different applications and requirements. We can provide you with the right product.